ara-nofo

| -kevi-pitantanana | Aluminum(5050 5052 5056 5154) | (AL Mg 1%-1.5%, 2%-2.5% ,3%-3.5%,5%) | ||

| farany | voalambolambo | RAL Color Painted | ||

| Mandrel | Aluminum ● | vy | Inôksa | |

| farany | Poloney ● | Zinc Plated | voalambolambo | |

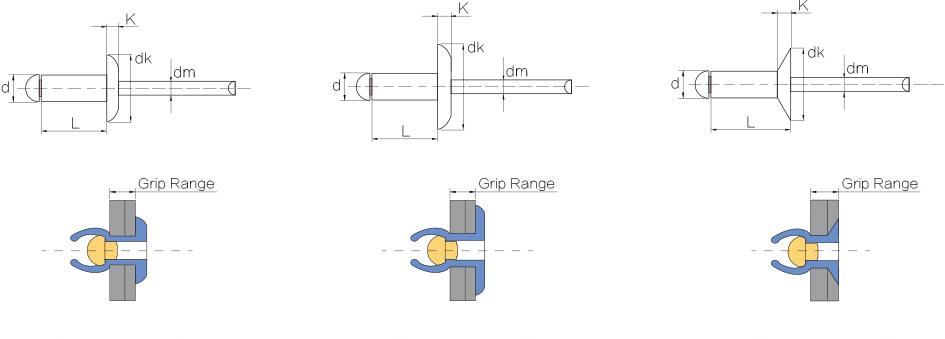

| Karazana loha | Dome, CSK, Flange lehibe | |||

famaritana

| D1 NOM. | DRILL NO. &Haben'ny lavaka | ART.CODE | GRIP RANGE | L(MAX) | D NOM. | K MAX. | P MIN. | Seara LBS | TENSILE LBS | ||

| mirefy | MM | mirefy | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0,032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0,250" 6.4 | 0,040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0,050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0,080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Fampiharana

Ny vy vita amin'ny aluminiana feno dia mampiasa tariby firaka aluminium avo lenta.Aorian'ny fametahana dia tsy harafesina na oviana na oviana.raha oharina amin'ny mahazatra rivets, ny rivet hamafin'ny dia ambany, noho izany dia mety ho mifandray amin'ny malefaka material.Aluminium pop rivets azo zaraina ho dome lohany rivets, countersunk rivets sy lehibe flange loha rivet.Ary ny aluminium firaka fitaovana manana safidy maro ny alu mg 2% 2,5% 3,5% ary 5% (5052 5154 5056).

Fixpal open type pop rivets dia manana tombony amin'ny asa mora, riveting tsara, bika tsara tarehy, fananana ara-batana avo.Safidy tonga lafatra amin'ny lafiny tokana riveting.Aluminium pop rivets dia azo ampiasaina betsaka amin'ny fiara isan-karazany, sambo, milina famokarana, elektronika, fitaovana, milina sakafo, fitaovana ara-pitsaboana, fanorenana, haingon-trano ary faritra hafa fastening.

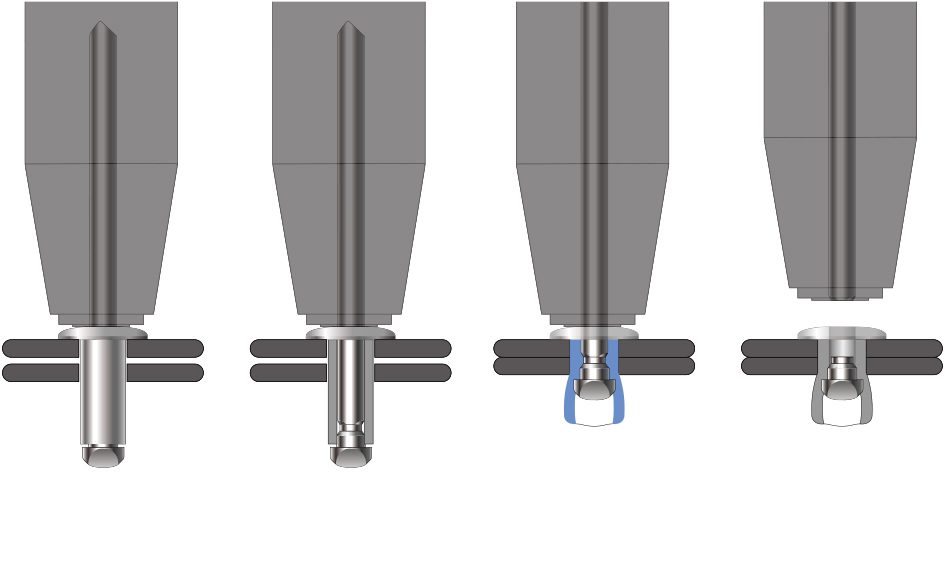

Ny olana sy ny antony rehefa mampiasa ny jamba rivet:

1. Burrs: Rehefa avy nively, ny mandrel tapaka miaraka amin`ny burrs mandalo amin`ny rivet lavaka;na mipoitra avy ety ivelany ny loaka mandrobona ka miforona spatula burr.

Ny antony mahatonga ny burrs: kely ny savaivony ny mandrel;malefaka ny fitaovana rivet;ny savaivony lavaka fandavahana ny workpiece dia lehibe loatra;ny mari-pamantarana moka amin'ny basy rivet dia lehibe loatra;

2. Mianjera ny lohan'ny fantsika: Rehefa voasintona ny rivet dia tsy azo fonosina ny lohan'ny fantsika ka latsaka avy ao anaty rivet.

Ny antony hianjeran'ny lohan'ny rivet amin'ny fotony dia: lehibe loatra ny savaivony ny satroka fantsika;fohy kokoa ny rivet, ary tsy mifanaraka ny hatevin'ny rivet.

3. vaky ny rivet: Rehefa vita ny fikosehana dia mipoitra na vaky tanteraka ny rivet.

Ny antony mahatonga ny famoretana ny rivet dia: ny hamafin'ny tafahoatra taorian'ny riveting annealing na unheated fitsaboana, ny fantsika satroka lehibe loatra.